Urethane Industries Applications

Urethane is an extremely popular plastic material to use for business needs and manufacturing. Not only is it cost-effective, but it also provides durability that many other plastic materials can’t. Due to the materials’ advantages, the polyurethane market is expected to hit $93.1 billion by 2026, growing at about a 5.8% rate annually. Keep reading this article to learn about urethane plastic and how it can help your business cut costs, improve manufacturing, and create more durable products.

Many different industries use urethane in their projects and applications. In this article, you can discover urethane industries applications, the differences, and similarities between urethane & polyurethane, and the cost benefits of the plastic material.

The application of polyurethane, as well as other types of urethanes, will continue to expand as more businesses realize its benefits. Keep reading to learn about urethanes and how they can enhance your business.

What Is Urethane?

Urethane is a term used to describe a group of substances whose chemical makeup consists of nitrogen, hydrogen, and oxygen. The three main substances are ethyl carbamate, carbamate, and polyurethane.

Urethane might appear as a white powder or clear crystal. The material has been heated with alcohol that contains an acid catalyst, making urethanes an ester of carbonic acid. The chemical formula for urethane is C3H7NO2, which is created by mixing a polyol and isocyanate that forms organic carbamate chains.

Want to learn more about urethane? Check out our blog “What Is Urethane and Why Should I Use it?” From reading, you will discover more information on why urethane is used in plastic extrusion.

Urethane vs. Polyurethane

The terms urethane and polyurethane are often used interchangeably. While they are extremely similar, there are some key differences as well. The “poly” portion of polyurethane simply indicates that it is made up of multiple groups of urethanes that are connected using polymerization.

Polyurethanes are typically firmer and more rigid than other urethanes. In addition, they are less toxic to animals and humans and can biodegrade faster.

What Is Polyurethane Used For?

Polyurethane applications include:

- Coatings, adhesives, and elastomers for various purposes

- Insulating fragile electric parts

- Waterproofing sealants from water and weather

- Durable custom tubing

- Irrigation system hosing

Inplex has worked closely with its partners to produce custom urethane solutions for many of the above industries. If you have a large custom urethane project that needs to be manufactured quickly and made with quality, Inplex is your ideal partner.

Cost Benefits of Using Urethane

The cost of using urethane in your business can vary greatly depending on the type of urethane, application, usage, and installation methods. However, it is often more cost-effective than other materials because of its durability. Because urethanes are able to withstand potentially damaging activities and conditions, you won’t need to replace them as often as other softer plastic extruded materials.

Some common examples of urethane usage include urethane extrusion, which can be more affordable than other types of plastic manufacturing.

For example, you could pay an upfront cost of $80,000 to make an injection mold for a piece of custom equipment.

On the other hand, you could invest about 80% to 90% less upfront to get the tooling necessary if you use polyurethane extrusion instead.

Other Benefits of Using Urethane Material

Besides being a cost-effective solution for business needs, there are many other advantages to using urethane, including

It resists heavy abrasions and wears and tear.

- It can be adhered to just about any other material.

- It resists damage caused by chemicals, solvents, oils, and grease.

- It can withstand heavy loads without permanent changes to its shape.

- It holds up against various weather conditions, such as long-term sun exposure.

- It can be used to reduce sound and vibrations.

Different Industry Applications Of Urethane

There are several industries that rely on urethane. This is due to the wide range of advantages the material holds. As mentioned above urethane works well bonding with other materials making it a popular material for all sorts of industries.

Polyurethane is recommended for applications that require a tighter bend radius. It provides excellent abrasion resistance, offering protection from oils and fuel. Its wide range of use means it’s often seen in a lot of industries, parts, and products.

Inplex mostly provides organizations with the following parts and applications made from Urethane.

- Roller covers

- Belting for conveyor systems

- Highway markers

Keep reading to discover just a few industries that benefit from the performance of urethane.

Plastic Conveyor Roller Sleeves and Covers For Manufacturing

Plastic conveyor roller sleeves streamline material transport for manufacturers. Inplex is proud to manufacture unique plastic components for modern warehouses, including conveyor roller sleeves, conveyor roller covers, and other custom plastic parts for your warehouse. Inplex helps organizations create efficiency with plastic conveyor roller sleeves and covers.

Discover our most requested plastic warehouse components for manufacturers:

- Conveyor Roller Sleeves- uses polyurethane

- Conveyor Roller Covers

- Plastic Rollers

- Plastic Flaps for Warehouse Doors

- Material Transport Plastic Parts

Polyurethane roller sleeves provide a softer, more flexible material that can be applied with an air tool to help it slide onto the conveyor roller. Polyurethane helps provide great durability which is highly sought after by manufacturers.

With Inplex as your plastic extrusion manufacturer, you can streamline your material transport, and discover a manufacturing solution. Polyurethane and urethane roller covers can also adhere to the conveyor rollers to fit the exact dimensions.

Custom Urethane Extrusion For Highway Makers

Polyurethane is changing the construction industry. In fact, the construction industry is one of the greatest beneficiaries of the material. Polyurethane is used in a wide variety of construction applications.

Here at Inplex, we manufacture high-quality, plastic pavement markers, sign poles, snow poles and posts, roadside delineator posts, and lane separator posts for all your highway safety extrusion needs.

- Pavement Markers

- Sign Poles

- Snow Poles & Posts

- Roadside Delineator Post

- Lane Separator Posts

It is recognized that many construction tools & machinery parts are made up of custom urethane parts. This is because the material is like rubber but happens to be stronger and provide minimum damage when pressed or rubbed against other materials.

Urethane parts are applied to create a variety of different tools needed. Inplex specializes in creating custom urethane parts for your exact project specifications. If you need a unique order of urethane pieces, custom urethane highway markers Inplex is the place to get it.

Polyurethane and Electrical Jacketing

Plastic coating and electrical jacketing are used to enhance the usability of most medals. These coatings are important because they help make metals safer to use, easier to clean, and longer lasting.

Polyurethane is known for providing excellent chemical and humidity protection and resistance. Because of these benefits urethane makes for an excellent coating to protect applications of critical electronic parts and components.

Inplex provides custom extruded plastic jacketing and custom plastic extrusion coatings for a variety of applications. If your order is above $5,000 USD please send us your application specifications for either, and Inplex will supply you with exceptional service and support. Due to our high demand for custom plastic extruded products, we are only currently accepting orders that meet those requirements. We do provide sample orders on a case-by-case analysis.

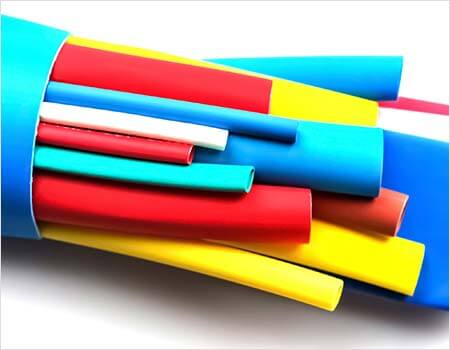

Polyurethane Custom Extruded Plastic Tubing

Inplex manufactures custom-extruded plastic tubing for your exact specifications and needs.

Plastic tubing can be constructed out of a range of materials, spanning from flexible to semi-rigid to rigid. When needing custom extruded plastic tubing made out of a flexible material your top choice is polyethylene tubing.

As mentioned above polyurethane is extremely flexible and has an excellent memory. This material is resistant to kinks and abrasions making it the perfect material to use when flexible custom extruded tubing is needed.

Custom Extruded Plastic Tubing

- Cut to length

- Wound on spools or coils

- Slit full length

- Printed to your specifications

- In-line fabrication

- Secondary operations

Stock and Custom Color Tubing

- Transparent

- Translucent

- Opaque

- Stock colors or custom match to your requirements

Choose the Best Urethane Supplier for Your Business

Choosing the right plastics supplier is essential to making sure your business runs smoothly. You should work with a company that understands your business and can provide exactly the materials you need.

Inplex Custom Extruders offers a variety of polyurethane products, including custom plastic tubing, plastic profiles, plastic coating and jacketing, and more. Inplex’s polyurethanes can come in a variety of colors to match your aesthetics, as well as varying rigidities ranging between flexible and semirigid.

Contact Inplex today to get a quote for your custom urethane extrusion orders that are above a minimum order of $5,000 USD. If you need a sample order, we are also able to provide those services as well!