Top 5 Industries Benefiting from Custom Plastic Extrusion

Custom plastic extrusion offers tailored solutions that meet the specific needs of diverse industries, providing benefits like material efficiency, durability, and precision. These advantages make it an essential manufacturing process for industries focused on innovation, cost-effectiveness, and performance.

Custom plastic extrusion plays a crucial role across multiple industries, offering versatility, precision, and cost-efficiency. Let’s take a look at the applications and benefits of custom plastic extrusion in 5 different industries.

Construction Industry

Applications

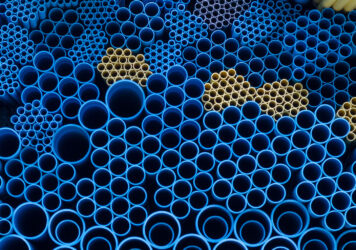

Custom plastic extrusions are widely used in construction for products like window frames, weatherstripping, siding, pipe systems, and insulation materials.

Benefits

Durability, resistance to moisture, and energy efficiency make extruded plastics ideal for construction materials. Custom extrusion allows for precise shapes and profiles, which improve installation efficiency and material compatibility.

Automotive Industry

Applications

The automotive sector uses custom extruded plastic parts for door seals, weatherstripping, wire harnesses, and interior components such as dashboard trim and ventilation ducts.

Benefits

Custom plastic extrusion provides the flexibility needed to create lightweight, durable, and weather-resistant parts, essential for vehicle performance and fuel efficiency. It also supports the demand for streamlined, aerodynamic designs.

Medical Industry

Applications

In the medical field, custom plastic extrusions are used to produce tubing for IV lines, catheters, respiratory devices, and other healthcare equipment.

Benefits

Medical-grade plastics need to meet strict health and safety standards, and custom extrusion allows for precise control over dimensions and material properties, ensuring biocompatibility and sterilization. It also supports innovation in new medical devices.

Consumer Goods Industry

Applications

From packaging materials to household appliances and electronics, custom plastic extrusions are used in a variety of consumer goods for items like protective casings, seals, and product components.

Benefits

Custom plastic extrusion enables the production of unique shapes and designs that enhance product functionality, durability, and aesthetics. It also supports mass production with cost-effective, high-quality materials.

Electronics Industry

Applications

Custom extruded plastics are used for wire and cable insulation, protective casings, electronic enclosures, and components in devices such as computers and telecommunications equipment.

Benefits

Plastics used in electronics need to be heat-resistant, flexible, and durable. Custom extrusion allows for precise insulation and protection, ensuring that components can withstand the stresses of electronic systems while meeting strict safety standards.

Custom Extrusion with Inplex

Looking for quality custom extrusion products and services? Inplex is one of the leading custom extrusion services in the US, with over 50 years of experience. We pride ourselves on our ability to put the right talent and technology in place to perform the best possible job for our clients.

We own a 42,000 sq. ft. facility in Naperville, Illinois, that is temperature-controlled and features an environmentally friendly closed-loop water cooling system. If you have specific needs or questions, don’t hesitate to contact us!

Back to Blog