The Role of Sustainability in Modern Plastic Manufacturing

Sustainability in plastic manufacturing is no longer optional; it is a critical aspect of modern business strategy. By adopting circular practices, investing in eco-friendly materials, and leveraging technology, manufacturers can reduce their environmental impact while maintaining competitive advantage. This shift ensures long-term viability and aligns with global efforts to protect the planet.

The industry is transforming its processes and materials to align with eco-friendly principles while maintaining efficiency and product performance. Let’s take a look at how sustainability is reshaping the field.

Emphasis on Circular Economy Practices

The transition from a linear “make-use-dispose” model to a circular economy is a cornerstone of sustainable plastic manufacturing:

- Recycled Plastics. Manufacturers are incorporating post-consumer and post-industrial recycled materials into production.

- Reusability. Designing plastic products that can be reused or repurposed to extend their lifecycle.

- Recycling Infrastructure. Investment in technologies to improve the sorting, collection, and reprocessing of plastics.

Development of Eco-Friendly Materials

The demand for sustainable alternatives has spurred innovation in materials:

- Bioplastics. Derived from renewable sources like corn starch or sugarcane, bioplastics reduce reliance on fossil fuels.

- Compostable Plastics. Products that break down naturally under industrial composting conditions.

- Advanced Polymers. Lightweight and durable polymers that improve product efficiency, especially in automotive and aerospace sectors.

Energy Efficiency in Manufacturing

Reducing the carbon footprint of plastic production is a key sustainability goal:

- Energy-Efficient Equipment. Advanced machinery minimizes energy consumption during extrusion, molding, and other processes.

- Renewable Energy Sources. Facilities are incorporating solar, wind, and other renewable energy sources to power operations.

- Process Optimization. Lean manufacturing techniques reduce energy waste and enhance overall efficiency.

Reducing Waste & Pollution

Efforts to minimize waste and prevent pollution include:

- Zero-Waste Manufacturing. Reusing scrap materials and optimizing production to eliminate waste.

- Ocean Plastics Recovery. Collaborating with environmental organizations to recover and recycle plastics from marine environments.

- Minimized Microplastics. Researching solutions to reduce microplastic release during production and end-use.

Regulatory Compliance & Incentives

Governments worldwide are driving sustainability through regulations and incentives:

- Plastic Bans and Restrictions. Limitations on single-use plastics to encourage reusable alternatives.

- Tax Benefits. Incentives for companies adopting sustainable practices and materials.

- Extended Producer Responsibility (EPR). Mandating manufacturers to manage the end-of-life of their products.

Long-Term Benefits

Sustainability offers tangible and intangible benefits to manufacturers:

- Cost Savings. Reduced energy consumption and waste lead to cost efficiency.

- Brand Loyalty. Eco-friendly practices enhance reputation and customer trust.

- Regulatory Preparedness. Proactive compliance with emerging environmental laws.

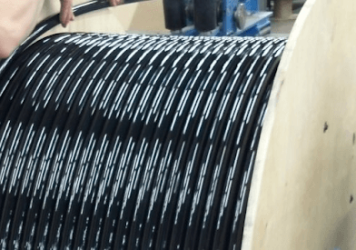

Custom Extrusion with Inplex

Looking for quality custom extrusion products and services? Inplex is one of the leading custom extrusion services in the US, with over 50 years of experience. We pride ourselves on our ability to put the right talent and technology in place to perform the best possible job for our clients.

We own a 42,000 sq. ft. facility in Naperville, Illinois, that is temperature-controlled and features an environmentally friendly closed-loop water cooling system. If you have specific needs or questions, don’t hesitate to contact us!

Back to Blog