Injectorplex Kryptonite Capillary Tubing

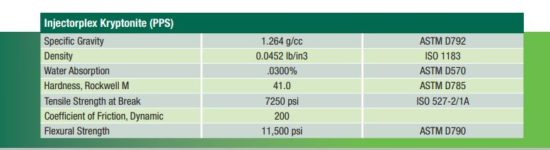

Kryptonite Capillary Tubing is a high-performance thermoplastic tubing that combines excellent mechanical properties with superb thermal and chemical resistance properties. With a Tensile Strength at Yield of greater than 17,000 PSI, and a weight of only 42lbs. per 1,000 feet, Injectorplex Kryptonite tubing offers the highest level of strength and corrosion resistance. Kryptonite is a linear, semi-crystalline, impact modified product. It is relatively impermeable to gases, hydrocarbons and other liquids compared to other materials.

Injectorplex-Kryptonite Capillary Tubing

Kryptonite provides high dimensional stability, low coefficient of friction, low shrinkage, and excellent mechanical properties.

Creep resistance at high temperatures, high continuous use temperature of 300°F and very low moisture absorption.

Kryptonite offers high tensile elongation, high hardness, rigidity and excellent resistance to corrosion, hydrolysis, oxidation, heat and paraffin buildup.

Shows excellent chemical resistance to all solvents below 340°F, acids, bases, typical and alternative automotive fuels and petroleum fluids at elevated temperatures.

Kryptonite Capillary Tubing: YOUR Source of STRENGTH

This semicrystalline engineering thermoplastic has exceptional thermal stability, superior toughness, inherent flame resistance, and excellent chemical resistance. It also has high mechanical strength, impact resistance, and dimensional stability as well as good electrical properties. Kryptonite also provides high mechanical strength and strength-to-weight ratio while maintaining dimensional stability over wide variations of temperature and moisture, with long-term property retention. Kryptonite is RoHS, PFOS, and PFOA regulation-compliant making it suitable for metal replacement applications. Kryptonite tubing will not kink and at 45 pounds per thousand feet, it is a fraction of the weight of stainless strings.

In order to compete in the oil and gas business, you need Injectorplex. Our value ensures that we understand completely, customize specifically, to manufacture exactly.

Send us your application specifications today!

Back to Blog