Injectorplex Injection Tubing: Stainless Steel vs. Plastic

With over 50 years of experience, Inplex has been creating custom extruded plastic tubing and plastic profile extrusions for various companies, including consumer housewares, outdoor living, and electrical. One of their latest projects is Injectorplex injection tubing, targeting the gas and oil industries with unique advantages that help to keep their products flowing smoothly.

With Injectorplex, Inplex has revolutionized the way gas and oil industries work. Their products provide solutions to common issues found in the stainless steel tubing industry. However, there are a few things to know when it comes to Injectorplex. Keep reading to discover more about injectorplex injection tubing as we dig deeper into stainless steel vs. custom plastic tubing.

Stainless Steel Tubing vs. Custom Plastic Tubing

Many oil and gas companies have opted for stainless steel tubing in the past, but this material comes with several bottlenecks that prevent it from being the best. For example, stainless steel tubing is expensive to extract and maintain. Coupled with its unreliability and short lifespan, it is far less superior to custom plastic tubing.

Stainless steel tubing is also prone to cracking and corrosion, and its short lifespan means that it needs frequent replacement. Thus, the cost of extraction and replacement can quickly add up in terms of time and money.

Using custom plastic tubing as injection tubing offers a solution to these common issues. First, it’s cheaper to extract and maintain than its stainless steel counterpart and it increases output on drilling sites. Additionally, it’s more durable and versatile than stainless steel, offering the following benefits:

- Increased lifespan

- Easily convertible

- Improved drilling equipment quality

- Greater return on investment (ROI)

With these advantages, it’s easy to see how Inplex’s Injectoplex injection tubing is replacing stainless steel tubing.

The Best Oil and Gas Injection Tubing: Injectorplex

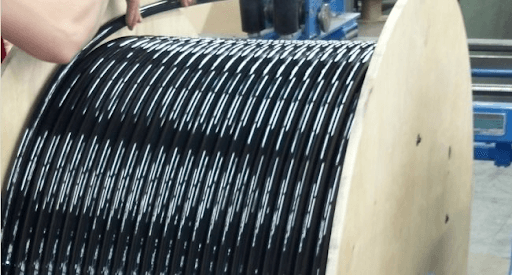

Since its introduction, Injectorplex injection tubing has quickly become a staple in the gas and oil industries. Made in the United States by experienced engineers, Injectorplex is the best oil and gas injection tubing on the market. Injectorplex is made from custom plastic tubing and aims to replace costly steel tubing. It’s made to withstand even the most severe H2S environments.

Injectorplex is manufactured from polyamide, making it flexible and resistant to abrasions, such as cracks, pits, corrosions, and extreme temperatures. Plus, its durability allows it to have a long lifespan.

Each Injectorplex transport tube is customized to fit individual specifications, with attention placed on tubing size and reel lengths for individualistic needs. It can also be further customized using two types of capillary tubing — titan and kryptonite.

Titan capillary tubing is a high-performance thermoplastic tube that provides economical benefits, tolerance against corrosion and H2S, and has an excellent weight-to-strength ratio. Titan capillary tubing can be customized even more into a dual titan, which allows further access to the cavity.

It also permits tandem cavity operation along with simultaneous bi-directional use. Titan capillary tubes are manufactured with up to 25% post-industrial recycled materials, making them even more eco-friendly.

Kryptonite capillary tubing is a versatile thermoplastic tube with high levels of tolerance to corrosion, strength, flames, and chemicals. It also has thermal stability, an excellent weight-to-strength ratio, and a good amount of mechanical strength. Kryptonite is less heavy than stainless steel and can be milled without kinking or balling up. This material meets all regulations set forth by Perfluorooctane sulfonic acid (PFOS), Restriction of Hazardous Substances Directive (RoHS), and Perfluorooctanoic acid (PFOA).

Inplex’s products are guaranteed to substantially enhance a project’s operations, and Injectorplex is no different. Not only will Injectorplex improve your operations, but it’ll also do so without harming the environment. It’s rigid, dimensionally stable, mechanically strong, and resistant to impact, ensuring that it will have the longest life possible. Regardless of the type of Injectorplex tubing you choose to work with, you’ll be sure to reap the benefits.

Top Features of Injectorplex Injection Tubing

Injectorplex injection tubing is far superior to stainless steel, surpassing it in many areas. Injectorplex injection tubing is a unique state-of-the-art custom plastic tubing that gives your organization a leg up in the oil and gas industry. Aside from the cost and increased lifespan, Injectorplex injection tubing also has the following benefits over stainless steel:

- High-temperature tolerance (up to 300°F) of constant use

- Resistant to chemicals, such as solvents, acids, bases, and oil fluids, as well as CO2 and H2S

- Excellent aversion to hydrocarbons and other fluids, paraffin accumulation, corrosion, hydrolysis, and more

- Outstanding mechanical strength, dimensional stability, and impact resistance

- Lower specific density compared to metal

- Resists alternative fuels and gasses, such as ethanol and methanol

- Better mechanical properties, including resistance to flow (creep)

- Improved flexibility, allowing the injection tubing to bend and conform as needed

- Lower friction and a decreased chance of blockage, meaning that fluids can flow through the tube more efficiently

Overall, Injectorplex injection tubing — and other forms of custom plastic tubing — have several benefits compared to stainless steel. These properties make custom plastic tubing the preferred choice for gas and oil industries that rely on precision. By working with Inplex you will find gas injection tubing solutions that fit your needs.

See How Inplex Influences Other Industries With Custom Plastic Tubing

Inplex has seen great success in providing custom plastic tubing to other industries. If you are looking for top extrusion options for custom extruded plastic tubing projects & applications turn to Inplex.

For example, Inplex offers a wide range of customization options that cater to your exact custom extruded plastic tubing needs. Unlike our competitors, our facility can manufacture a high volume of reliable custom plastic tubing projects. This includes plastic tubing for the outdoor living industry and plastic tubing for consumer houseware applications like irrigation hoses and pipes. You can count on us to get your next plastic extrusion project done the right way.

Contact Inplex to Get Injectorplex Injection Tubing

Inplex boasts over 50 years of experience in the plastic extruded industry. As you can tell Injectorplex is revolutionizing the oil and gas industries, and it’s replacing stainless steel tubing. Our custom plastic tubing for the oil and gas industry comes with great benefits such as an increased lifespan, and greater return on investment.

Efficiency, economy, and reliability will move your organization to achieve a greater profit. Inplex’s value guarantees thorough comprehension, tailored customization, and precise manufacturing. You just need Injectorplex injection tubing to compete in the oil and gas industry.

Send us your injection tubing application specifications today.

Back to Blog