Flexible Vinyl: Best Uses, Benefits, and More

Flexible Vinyl or PVC (polyvinyl chloride) is a soft plastic ideal for use when both elasticity and durability are crucial. Flexible vinyl provides superior elastomeric performance and can be made heat- and weather-resistant depending on the application requirements.

It is most commonly used in the construction and medical industries but has the potential to be customized for a wide range of processes. Flexible PVC (FPVC) is also unique in offering a huge variety of finishing and coloring options to improve aesthetic appeal.

Since its introduction in the 1930s, the usage of PVC has rapidly increased worldwide. It is the world’s third-most manufactured synthetic plastic polymer today. Flexible PVC, in particular, is extensively used in air lines, pump lines, and water lines.

How Is Flexible Vinyl Made?

Unmodified PVC is naturally rigid. In order to make raw PVC fit for industrial use, additives like heat stabilizers, UV stabilizers, flame retardants, impact modifiers, and blowing agents are added.

Specifically, plasticizers are added to improve the flexibility and elasticity of the vinyl. Plasticizers act as lubricants by increasing the space between the polymer chains. This results in the material losing some of its rigidity and it is no longer as brittle. Adding plasticizers makes the material softer and lowers the glass transition temperature.

Many different substances such as phthalates, trimellitates, adipates, and epoxidized vegetable oils can be used as plasticizers. Specific plasticizers for a project are chosen according to installation requirements.

The flexible PVC produced has distinct physical and chemical properties depending on the type and amount of plasticizer used. There are also various standards and regulations that limit the amount of additives that can be used based on usage and application. For example, FPVC packaging that is used for blood or IV bags in hospitals must be medically approved.

What Are the Benefits of Flexible Vinyl?

Flexible vinyl is strong and pliable, which makes it an extremely versatile material that can be employed for a great variety of purposes. A major benefit of using FPVC is that it is compatible with a number of additives.

By using different additives in varying amounts, or a combination of them, a wide range of hardness can be achieved. Because of this extraordinary adaptability, FPVC is used by a number of industries on a large scale.

Some of the greatest advantages of flexible PVC are:

- Low cost

- High flexibility — easier to process than rigid PVC

- Good electrical insulation properties

- Non-flammable (self-extinguishing)

- High clarity

- Resistant to weathering and corrosion by most inorganic chemicals

- High strength and abrasion resistance

- Broad range of hardness

- Light-weight

- Recyclable

Use of Flexible Vinyl

Flexible PVC is inherently versatile and is used for applications ranging from drainage pipes and window frames to fabrics and credit cards.

Household Uses

The most frequent applications of flexible vinyl in the household include cling films, shower curtains, hose pipes, and floorings.

Automotive Uses

The automotive industry also utilizes FPVC in the form of interior moldings and panels, sun visors, seat coverings, and underbody coatings.

Other Common Uses

FPVC can be cast to create smaller products. The smooth surface of vinyl helps ensure there is no buildup of sediments even over relatively long periods of use.

Some of the most familiar applications of FPVC are:

- Cable and wire jacketing

- Door and window components

- Office equipment

- Film and fabric coatings

- Toys and bottles

- Rainwear and boots

- Tents and tarpaulins

- Automotive interiors

Using Flexible PVC for Pipe Extrusion

One of the most economically significant applications of flexible PVC is pipe extrusion. It offers a lot of the same properties as vulcanized rubber but is easier to mold. Flexible vinyl offers easy processing and can be extruded using traditional thermoplastic manipulation equipment.

As a result, the construction, transport, electrical, and medical industries make extensive use of FPVC pipes and tubing. Because of its good mechanical properties and adaptability, flexible vinyl piping is ideal for flooring, lining, waterproofing, and insulating purposes.

The most common applications of FPVC extrusions are:

- Water plumbing

- Chemical transfer and delivery

- Infrastructure materials

- Garden hoses

- Medical tubing

- Electrical cable insulation

- Waste handling and control

Inplex Is Your Flexible Vinyl Manufacturer

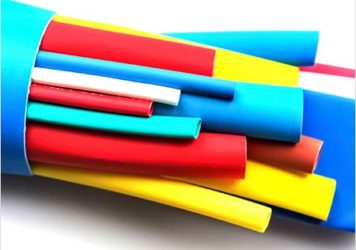

Inplex offers a range of custom extrusion services and delivers quality products that are tailored to your needs. Our FPVC pipes and tubing are available in an endless variety of profiles, opacity, and coloring.

Inplex is the leading supplier of extruded plastic tubing & profiles that bring superior performance and durability. We provide multifunctional tubing with its mechanical, electrical, and chemical properties customized to your specifications.

To learn more about how we can help with your extrusion requirements, browse through the different industries we provide flexible vinyl to or request a quote for your next project.

Back to Blog