Common Applications of Custom Plastic Tubes Pt. 1

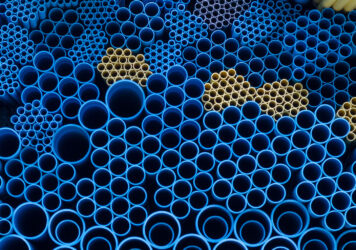

Customized plastic tubes are integral to many industries due to their versatility and adaptability, offering tailored solutions for various applications. The application of custom plastic tubes is nearly limitless.

This article aims to showcase how custom plastic tubes can be used as parts and components in a huge variety of applications. Many times custom plastic tubes are not the final product–they are simply very important parts of the final product.

Let’s take a look at several industries and settings where custom plastic tubes are used and what they are commonly used for.

Medical Applications

Medical Devices

Plastic tubes are used in catheters, IV lines, and other medical devices that require biocompatibility and sterilization. They are often customized for flexibility, size, and material properties suitable for human contact.

Delivery Systems

Tubes are used for the precise delivery of medications in applications like inhalers, syringes, and transdermal systems. They may be designed for controlled release or specific flow rates.

Laboratory Equipment

Plastic tubes are utilized in lab settings for transferring fluids, gas sampling, and as components of diagnostic equipment. They often need to be chemical-resistant and transparent.

Food & Beverage Industries

Beverage Systems

Tubes are utilized in soda fountains, coffee machines, and other beverage dispensing equipment. They are designed to meet food safety standards and maintain taste integrity.

Pipe Systems

Plastic tubes are chosen for their chemical resistance and ability to withstand high temperatures when processing plants transport liquids and semi-solids.

Automotive Applications

Fluid Transfer Systems

Plastic tubes are used to transfer fluids like fuel, oil, coolant, and brake fluids within vehicles. They are customized for high-temperature resistance and durability under harsh conditions.

Air & Vacuum Lines

Tubes are used in HVAC systems, air intakes, and vacuum lines for their flexibility and resistance to pressure changes.

Wire/Cable Protection

Plastic tubing protects wiring and cables from abrasion, moisture, and heat in the engine compartment and throughout the vehicle.

Construction/Building

Cable Management

Plastic tubes serve as conduits for electrical wiring and fiber optic cables, protecting them from environmental damage and making installations easier.

Plumbing

Used for water supply lines, drainage, and wastewater systems, plastic tubes are valued for their resistance to corrosion and ease of installation.

Insulation

Tubes are used as insulation for pipes, preventing heat loss and condensation in HVAC and plumbing systems.

Custom Extrusion with Inplex

Looking for quality custom extrusion products and services? Inplex is one of the leading custom extrusion services in the US, with over 50 years of experience. We pride ourselves on our ability to put the right talent and technology in place to perform the best possible job for our clients.

We own a 42,000 sq. ft. facility in Naperville, Illinois, that is temperature-controlled and features an environmentally friendly closed-loop water cooling system. If you have specific needs or questions, don’t hesitate to contact us!

Back to Blog