Who is Inplex? An American Plastic Extrusion Company

In today’s global economy there are companies that do basically everything you could imagine. From fulfilling the basic needs of the global populace to addressing niche markets like fuel delivery. So who is Inplex? An American plastic extrusion company based in Illinois.

The plastics industry in the United States is large, and it is growing in volume and importance in national and global markets. According to the Plastics Industry Association, in 2020, the American plastics industry shipped $394.6 billion worth of products and provided over 1.5 million people with jobs. Inplex Custom Extruders LLC has been a part of the American plastics industry for more than five decades, and they are still going strong.

Inplex custom plastic extrusions are found in many of the everyday items you find around your home, like lawn furniture, pipe fittings, kids’ toys, playsets, etc. The chances are good that you own something created by, or which contains parts created by, a plastic extrusion manufacturing company, perhaps even by Inplex. They also build customized parts, tools, and equipment for many large industries, including food preparation, road, home construction, wire and cable manufacturers, and much more.

Who Is Inplex Custom Plastic Manufacturing?

Inplex Custom Extruders LLC is a privately owned company founded in 1967. For over 50 years we have been providing some of the best custom plastic extrusion products on the market.

Today, we currently employ 62 people at our 42,000 square-foot facilities in Naperville, Indiana. Our entire custom plastic manufacturing facility is temperature-controlled and even includes an environmentally friendly closed-loop water cooling system. Sustainability and eco-friendly initiatives are important to our company values.

At Inplex, we believe that our employees are our most valuable asset, and our employees have rewarded our appreciation with loyalty. The average length of employment at our plastics manufacturing facility is 16 years and counting. At Inplex we aren’t just a company, we’re a family of hard-working individuals invested in the success of our clients.

Part of the reason Inplex has found success is the importance we place on our customer’s satisfaction with our custom plastic products. With a devotion to getting each and every order right the first time, fully customizable options, the use of high-quality materials to create the highest quality products, and excellent customer service, it is no wonder that our customers are loyal, too.

What Does Inplex Manufactrure?

What Does Inplex Manufactrure?

The team at Inplex has learned a thing or two about plastic extrusion during their time in business, and it shows. They use the newest technology and techniques, like plastic co-extrusion and tri-extrusion, to create custom plastic projects that will meet each customer’s specific needs.

The Inplex facility offers customers almost 100 different resins from which to choose. These include commodity-grade and engineered resins like Urethanes and Nylons. Their skilled team of workers has experience running everything from the coating used to cover wire and conduits to tubing and pipes and many projects in-between.

Industries Served by Inplex Plastic Extrusion Products

Inplex has developed a reputation for providing high-quality extrusion plastic products to customers large and small. This has allowed them to expand into many different markets and industries, including:

- Food grade and non food-grade packaging materials

- Manufacturing

- Industrial

- Medical

- Construction

- Oil and gas production

- Vehicle production and maintenance

Inplex has worked with several high-profile company partners to create specific custom projects. Check out our work creating a custom plastic pergola in our recent blog Why Top Brands Choose Inplex for Custom Plastic Components in Outdoor Products.

Our team has produced a variety of different products. Here’s a quick look at some of the most common plastic products we’ve manufactured:

Spray and Aerosol Dip Tubes

One of our most commonly produced products is our plastic tubing for spray and aerosol dip tubes. These types of tubing and be found in everything from spray bottles to soap dispensers. These types of tubing are critical to the numerous plastic and aerosol products that millions of people use every day.

At Inplex each of our plastic tubes is manufactured according to the highest industry standards. With our custom plastic tubing products, you can avoid issues associated with poor-quality dip tubes, such as residue build-up and tubes becoming stuck while in use.

Lawn Sprinkler System Tubing

Another common use for our leading quality plastic tubing is outdoor lawn and garden irrigation systems. With our custom tubing profiles, you can choose to have them as flexible and long as you want which allows for positioning around plantings, hardscapes, uneven terrain, terraces, and more.

Not only is our products flexible, but they also can come with a customized look. Choose opaque or transparent, flexible or rigid, and we will tailor the specific custom plastic profiles that you can use in your backyard or home.

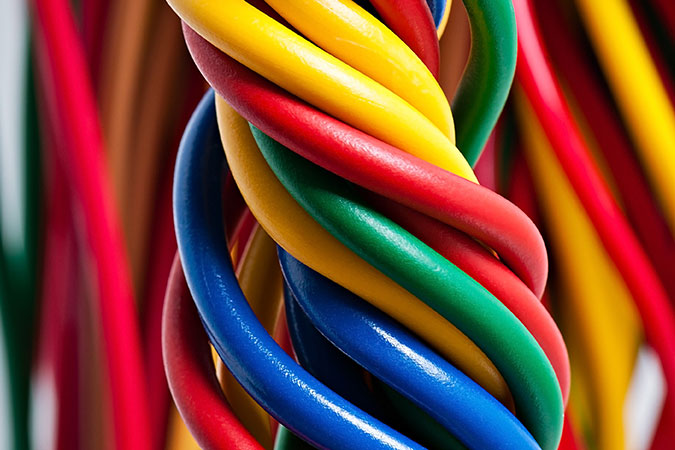

Plastic Extrusion Coating for Electrical Utilities

Plastic Extrusion Coating for Electrical Utilities

Inplex can also create custom plastic extrusion coating to protect metal wires, bars, and tubes from harsh conditions. Our Dual Durometer plastic manufacturing capabilities allow us to create different hardnesses, or in plain speak we can manufacture a plastic coating to be as rigid or flexible as you need it to be.

Inplex provides custom jacketing solutions for the following:

- Coated conduit

- Guy wire guards

- Raceways

- Coated wire

- U Channels

- Busways

With our custom durable plastic coating, you can lengthen the life of your wiring materials and also protect against exposed wires.

LED Channel Strip Covers and Lens Covers

Looking to create the perfect lighting ambiance, or need to cover some lights with custom covers? Inplex also creates custom plastic light covers for lighting and LED light strips. With our unique plastic manufacturing capabilities, we can also manufacture custom lens covers.

Here’s a glance at some of the uses of Inplex LED channel strip covers:

- Empower you to use LED strip lights like a traditional lighting fixture. For example, if you want to attach LED strip lights around your house, you can get a U-shaped LED channel strip cover to attach to your LED lights.

- Limit direct glare. Without LED channel strip covers, your LED strip lights may shine directly into your eyes, causing discomfort.

These are just a few of the unique custom plastic products Inplex has created for past clients. You can learn more about products we’ve created in our recent blog, Products In Your Everyday Life That Are Manufactured By Inplex.

At Inplex our unique manufacturing capabilities allow us to create custom projects and parts for a large variety of different industries. We continually strive to offer our services to new products and industries where quality plastic extrusion products. Just let us know what your project specifications are and our team of plastic extrusion experts can help set up your project.

Quality Ensured Plastic Products

Another aspect that sets Inplex apart, aside from our diverse capabilities and customer service, is the extreme commitment we have to quality products.

At Inplex our commitment to quality is unmatched. Our team has multiple certifications, qualifications, and processes to ensure the level of quality for our customers.

Inplex ISO 9001:2015 Certification

Inplex once again received an International Organization for Standardization (ISO) 9001:2015 audit of our quality management system. The ISO is an internationally recognized standard for quality management.

For the ninth consecutive year, Inplex fulfilled the requirements and received re-certification, with zero minor and zero major non-conformances. This audit included areas such as sales and order entry, production, calibration, production equipment, and purchasing. Each area was audited and re-certified by an independent auditor. Our years of certification demonstrate that Inplex is a well-established manufacturer with reliable and consistent standards in their custom plastic products.

Inplex’s IMS Certification

Inplex also boasts Integrated Management System (IMS) certification.

Our IMS integrates all of our processes and systems into one framework, enabling us to work as a single unit with unified goals. Accordingly, we apply quality management standards during every stage of the manufacturing process. This provides several benefits, including high production quality, minimal downtime, faster time-to-market (TTM), and improved customer experience.

In contrast, non-IMS organizations focus on management systems individually. Quality assurance is typically delegated to a quality team that only implements quality control after specific manufacturing stages. This can result in oversight, miscommunication, and longer downtime.

Other Quality Control Measures

At our facilities, Inplex also uses the Admet eXpert 7601, Non-contact laser micrometers, and QDA 9 Datamyte to ensure the quality of our products. Learn more about how we ensure quality in our recent blog, Quality Assurance for the Best Plastic Extrusion Products.

Inplex Continues To Be a Leader in Custom Plastics Manufacturing

Inplex has survived and thrived through the many changes in the manufacturing industry over the past 50 years by always looking forward and adapting as necessary. We strive always to have the best talent paired with the newest technology to create the high-quality parts that customers need and deserve.

The Inplex strategy of commitment to quality, employee retention, and top-level customer service has led to the company being a successful and financially secure business. Their current total sales volume has topped $13,000,000.00, and they intend to keep looking onward and upward as they continue to be a proudly American-owned and operated plastics manufacturer.

Looking for a quality plastics manufacturing partner for your next custom project? Contact Inplex and speak with one of our plastic manufacturing experts today. We can assist you in determining the specifications for your next custom plastics project and answer any questions that you might have.